Gas: Regulator Stations

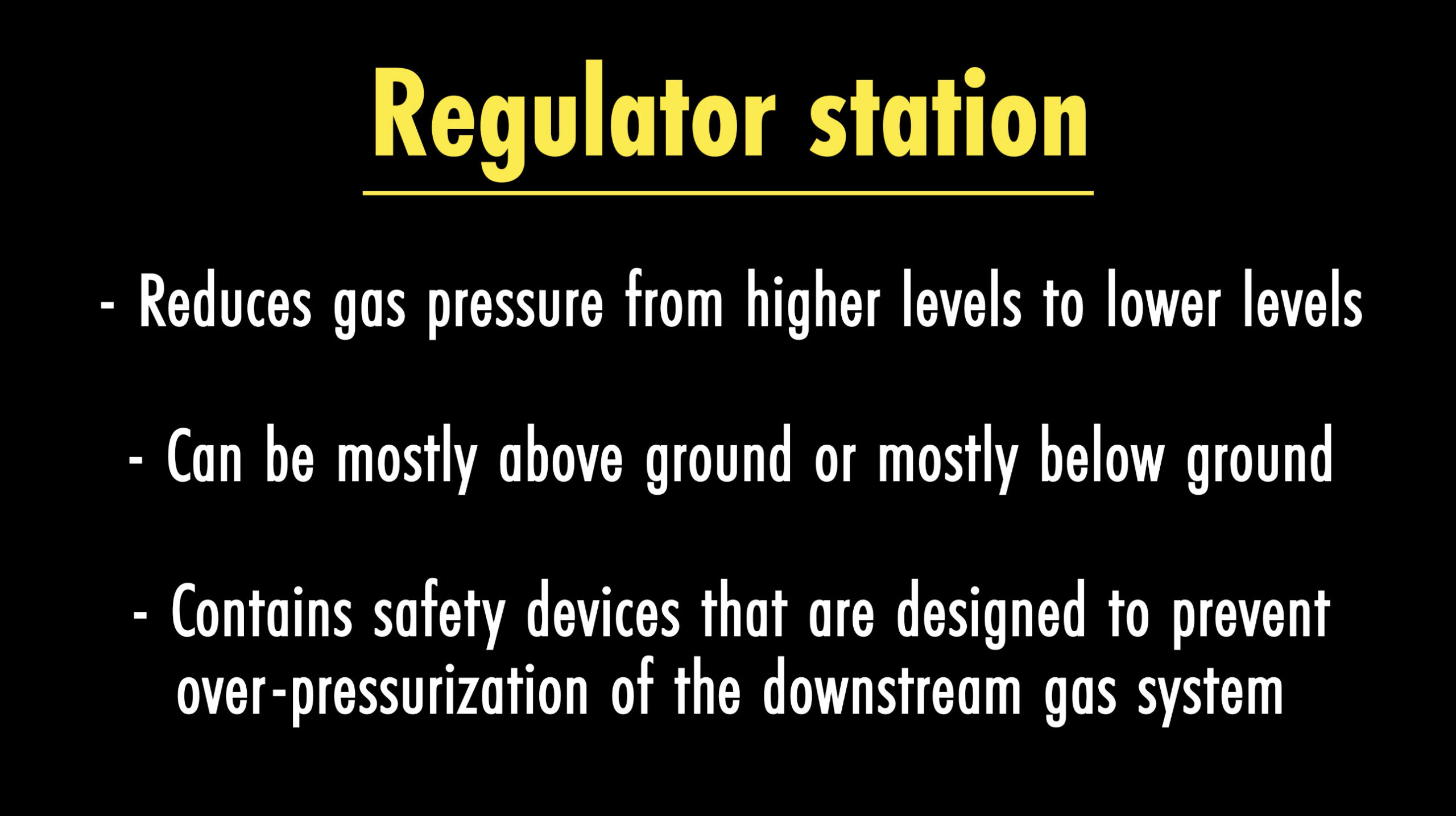

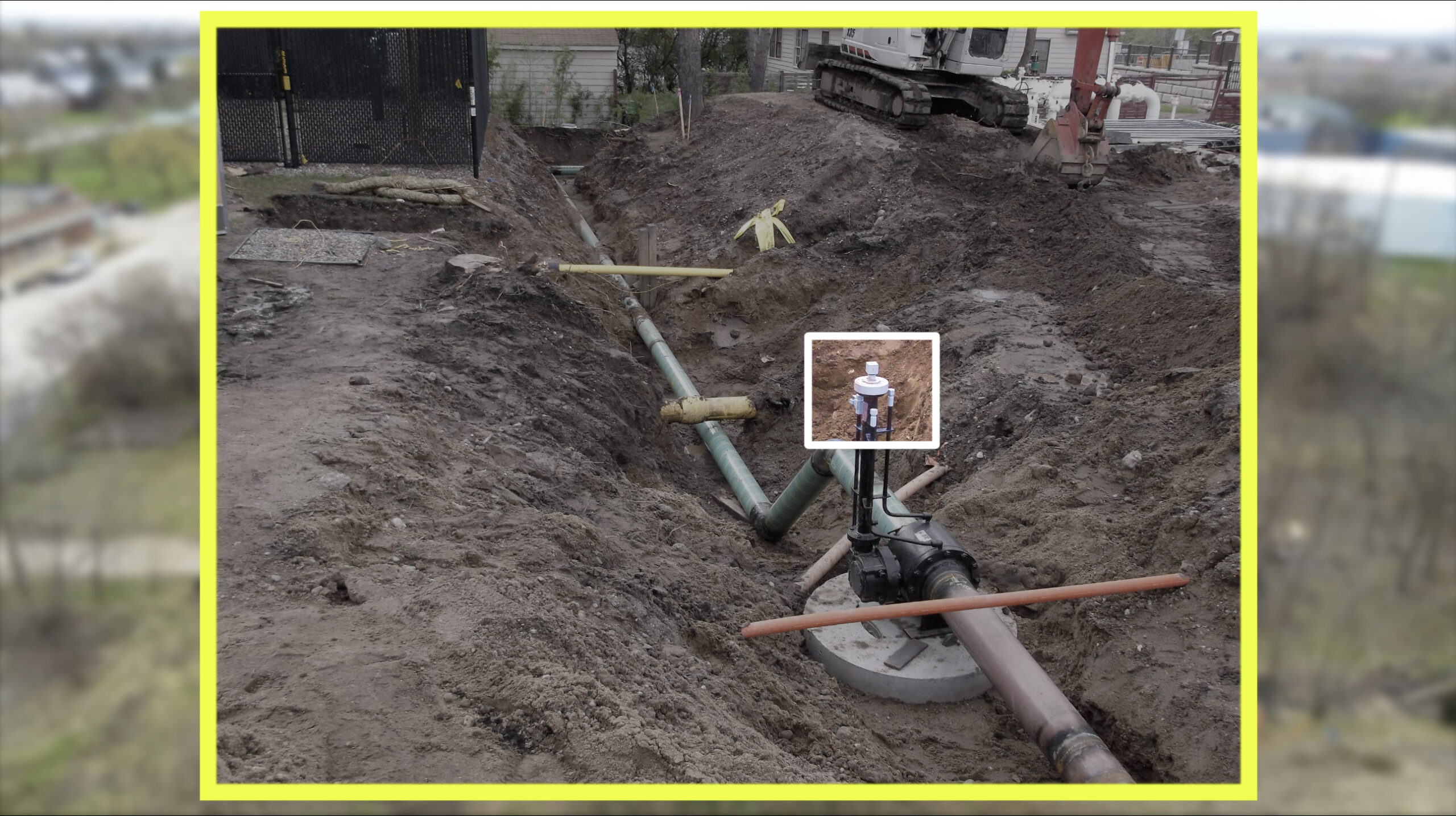

At this location along the high-pressure pipe sits a regulator station (Figures 29-31). A regulator station takes in higher pressures of gas—300, 250, 200 pounds—and then reduces that to the distribution pressure—50, 60 pound systems. Again, 60 pounds is the maximum pressure within a typical distribution system.

Figure 29

Figure 30

Figure 31

Within the distribution system, the pipes then can be plastic or steel, but you won’t have plastic pipes (Figure 32) where the pressure exceeds 60 pounds.

Figure 32

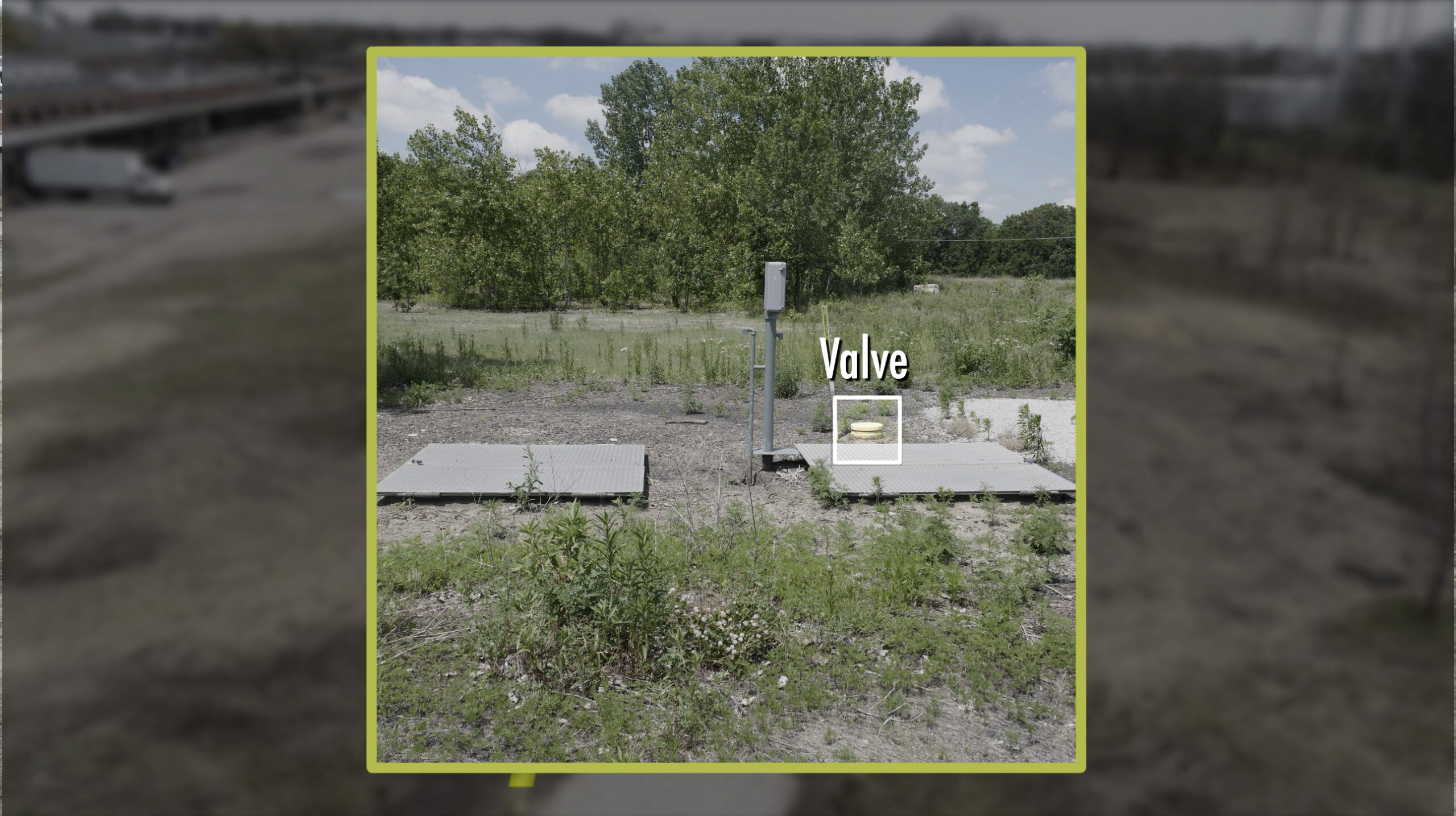

A gas regulator station can be above ground (Figure 33), or it can be below the ground (Figure 34). Below ground regulator stations will always have a vent pipe above the ground in case the regulator station needs to vent the gas.

Figure 33

Figure 34

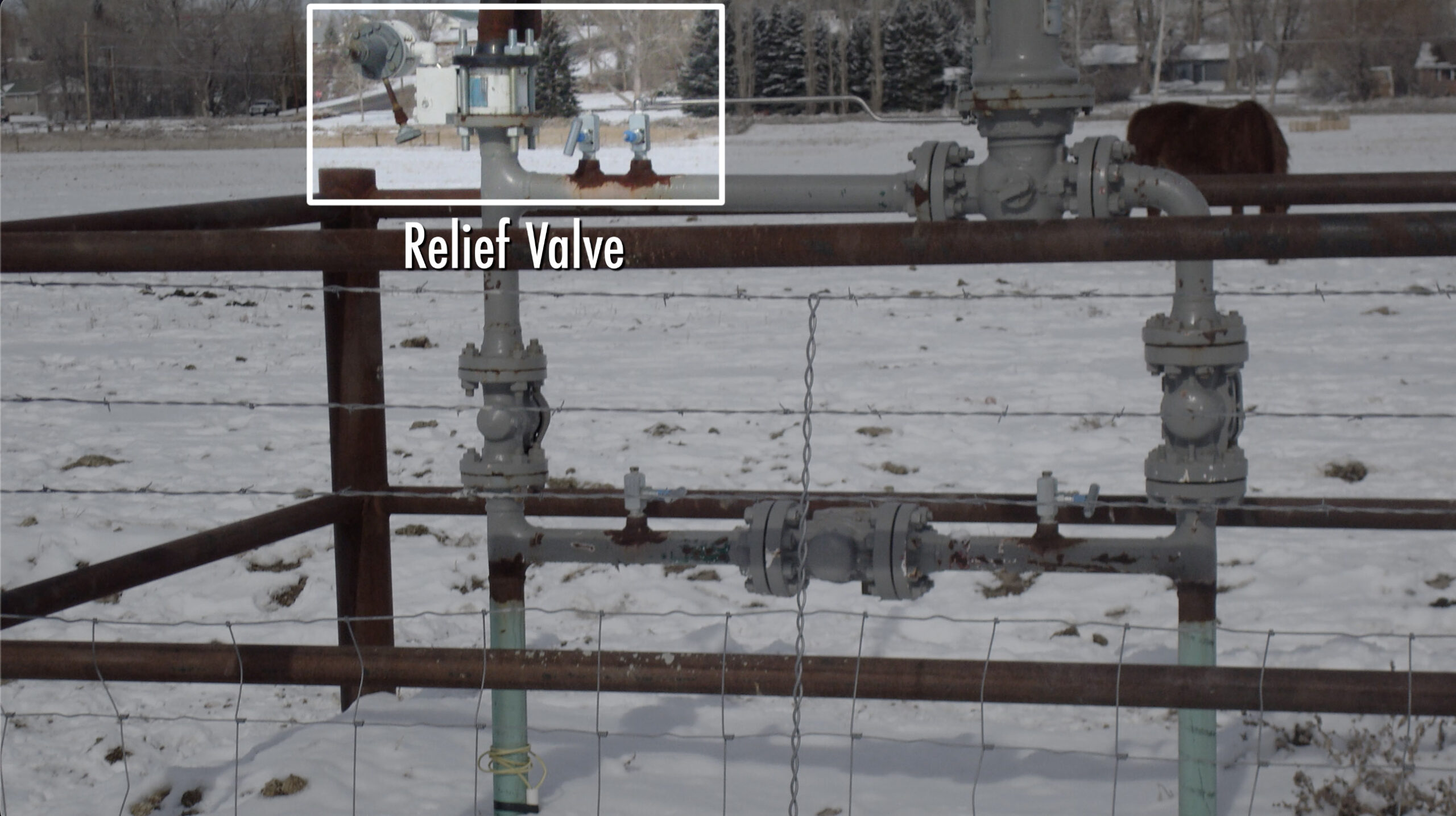

If the amount of gas flowing reaches a certain point that is considered to be too much flow, the regulator station can reduce the flow of gas by shutting down the regulator. This could occur if there’s a damage or another sort of system failure downstream. To provide safety, all regulator stations will have relief valves (Figures 35-36) where the gas can vent to atmosphere if there’s an issue.

Figure 35

Figure 36

A regulator station has high and low-pressure limits. The high-pressure limit is generally 60 pounds. Within the regulator station are devices to measure pressure and flow, and these devices can prevent an accident involving over-pressurization of the downstream system. We recap the key points below (Figure 37).

Figure 37

This is a pneumatic actuator (Figure 38), and it uses the pressure of the flowing gas to close the valve. Connected to a communication system, the valve can be opened or closed remotely.

Figure 38

Newer plastic mains are yellow in color, while older plastic mains could be more of a peach or light orange color (Figure 39).

Figure 39